Archaeology : Architecture : Art : Cold War : Curiosities : Design : Eccentricities : Ekco : Engineering : Industrial Heritage : Military : Petroliana : Photography : Shed Wonders : Transporter Bridges : Vintage Technology

29 May 2014

Clifton Suspension Bridge - 150 Years

Although one of Brunel's masterpieces, the Clifton Suspension Bridge was neither completed during his lifetime, nor to his design. Commenced in 1831, the structure at Clifton was of the very first generation of wrought iron chain suspension bridges, absolutely at the cutting edge of the engineering of the time. Built at Clifton to take advantage of the relatively narrow width of the Avon Gorge at that point, the deck is 245 feet above high water.

A first design competition was conducted in 1829, three years after Thomas Telford had built his suspension bridge over the Menai Straits. The competition committee asked for Telford's expert opinion on the entries, which included four by Brunel. Telford declared all the designs flawed, and was asked by the committee to submit his own scheme. His short-span suspension bridge was responded to with a new, cheaper, design from Brunel.

Accordingly, a second competition was held in 1830. Smith and Hawkes' scheme was selected as the winner, and Brunel's abutment-based design placed second. Brunel, aged just 24, managed to reverse these placings after private meetings with the committee's expert advisers, and work commenced in June 1831. Four months later a shortage of funds, and riots in Bristol, brought progress to a halt. Work did not re-commence until August 1836, starting with the abutment on the Leigh Woods side. That on the Clifton side, left of picture at top, was commenced in 1839.

The abutments, of grey Pennant rubble stone faced with dressed Old Red Sandstone, are of different heights, to account for the taller and steeper cliff on the Clifton side. They were thought solid until found, in 2002, to be formed of a series of massive chambers. By 1840 the towers, 702 feet apart, 86 feet high, and of about 4,000 tons each, were complete. Next came the anchorages, inclined tunnels cut 60 feet into the cliffs, into the depths of which are carried the ends of the chains. These are locked behind cast iron anchor plates, of 30 square feet, bolted to the rock, and reinforced by 10 feet of Blue Staffordshire brickwork. These were completed in 1842, in which year the towers were topped with cranes to enable construction of the chains.

The chain links, the shortest 24 feet long, had largely been delivered when funds again dwindled. By 1848 the Copperhouse Foundry, Hayle, Cornwall, that had made the links, issued proceedings for payment of its invoices. The debt was repaid only through sale of the chain links, which ended up on the Royal Albert Bridge at Saltash, also by Brunel. The Clifton project came to a second halt in 1853.

Brunel died in 1859. The following year John Hawkshaw designed the Charing Cross railway bridge. This replaced Hungerford Suspension Bridge, another Brunel construction, and Hawkshaw and fellow engineer William Barlow proposed that the Hungerford ironwork be used at Clifton, the links being of the same design as those sold for the bridge at Saltash.

Hawkshaw and Barlow made some design changes - longitudinal deck girders instead of timber trussing, a third chain, and new anchorages - and work re-commenced in November 1862. The Hungerford saddles were installed atop the towers in 1863, and eight wrought iron cables were strung across the void, to provide temporary falsework. The chains, of 4,200 links, were in place by May 1864.

The deck is attached to the chains by way of iron rods, which are in turn bolted to the bottom, middle and top chain, to ease replacement. Once the longitudinal girders were craned into place, the cross bracing was undertaken. The deck itself was formed of five inch thick Baltic pine, laid in two layers, at right angles to each other. The bridge finally opened on 8 December 1864.

The roadway was first asphalted in 1897, and the anchorages strengthened in 1925 (Leigh Woods) and 1939 (Clifton), but, in the main, the structure is just as it was 150 years ago. No steel cables have been added, as has proven necessary with some other early suspension bridges. Brunel didn't see the completed bridge, but he would have known that it was, and is, an engineering marvel.

Labels:

Architecture,

Engineering,

Photography

Clifton Observatory

A splendid view of the Clifton Suspension Bridge can be had from a balcony cantilevered out from the mouth of Ghyston's, or St Vincent's, Cave, 90 feet below the top, and 250 feet above the foot, of St Vincent's Rocks.

The tunnel to this, excavated by the artist William West, is accessed from the nearby Grade II listed Observatory. This started life in 1766 as a corn mill, was later used to grind snuff, and was abandoned in 1777 when a strong gale over-drove the sails and set light to the mechanism.

West rented the mill from 1828, used it as his studio, and installed a camera obscura. He also determined to link the Observatory to Ghyston's Cave, previously accessible only via the cliff face. The cave has at times served as a chapel, is first mentioned as such in the early fourth century.

The tunnel, through limestone, is 2,000 feet long, took two years to cut, and first opened in 1837. Stone and brick steps make an initial descent, which is continued more gradually by way of concrete steps. A metal stairway drops into the cave, from which there are steps up to the suspended balcony.

Labels:

Archaeology,

Curiosities,

Eccentricities,

Mining

20 May 2014

Good Head, Croydon

At the heart of Park Hill, Croydon, stands a water tower, built in 1867 above a pre-existing reservoir of 1851. The latter was constructed underground. Circular brick walls 30 feet high were capped with a domed roof. Of 75 feet diameter, the reservoir held a maximum of 950,000 gallons. Unfortunately, this facility proved incapable of serving the luxury properties built upon the higher ground on the then outskirts of Croydon, and the tower was constructed to provide suitable water pressure.

30 feet in diameter and 100 feet high to the top of the turret (excluding the 25 feet below ground), this was designed by Baldwin Latham, Borough Engineer, in a pseudo-Norman style. It incorporated a cylindrical wrought iron tank of 40,000 gallons capacity, borne on cast iron girders and intervening timber joists. Additional support of the tank came in the form of the central cast iron inlet, outlet and overflow pipes.

In the basement of the tower was an additional tank of 94,000 gallons capacity, on a level with and connected to the earlier reservoir. This lower tank had an internal diameter of 27 feet, with a brick and stone pier at its centre, supporting the pipes to the upper tank. The water stood 27 feet deep. The whole structure stands upon four feet of concrete, the walls 5 feet 5 inches thick at the bottom of the lower tank, of 3 feet 2 inches at ground level, and 14 inches thick at the tower's top.

In the late nineteenth century the tower could be climbed, by stairs, to access a viewing platform and, indeed, during WWI was used as a lookout for Zeppelins. Its water-providing abilities ultimately proved inadequate, and the site was abandoned in 1923 subsequent to construction of a new reservoir in the Addington Hills, although the old reservoir provided a source of water for fire-fighting during WWII. The tower was Grade II listed in 1970, but the tanks and internals are all gone, and the building remains abandoned, although thankfully secure.

Labels:

Architecture,

Engineering

16 May 2014

Taywil Hero Mangle Press

Taywil Hero Machine mangle disassembled and all elements wire-wheeled. Cast iron frame drilled for bolting-in of print bed support, and painted with three coats of red and two coats of black metal paint. Components painted with two coats of black paint, bearings stripped and regreased, and springs replaced. Components test assembled.

Wooden rollers treated for woodworm, and turned down on a lathe to a reduced diameter. Rollers sheathed with stainless steel tubes of ¼" wall thickness - the most expensive items of the project. Drive and transfer wheels re-fitted and painted as per frame and components, and handle coated with two applications of sealing woodstain.

Print bed support fabricated from 2" wide steel bar, drilled to enable bolting to frame and to take stretchers, and painted as per components. Stretchers made from M10 threaded rod, bolted through steel bar supports, and positioned such that rod tops are just below mid-line between rollers.

Rollers installed and transfer wheels cover fitted. Strips of wood fitted underneath original wooden top board, with a small gap between - to hold printing paper out of the way until nipped by rollers - and treated as per handle. Print bed can be sealed medium density fibreboard (MDF) or sheet steel. Mangle now a printing press, for linocuts, plate engravings and etchings, and woodblocks (up to tooth depth of transfer wheels), to a maximum of 20 inches wide.

Taywil was a brand of Taylor and Wilson, of Clayton, near Accrington, Lancashire. Founded in 1866, they made washing and mangling machines, and step-ladders. Later Taywil's trade listings included gas-heated boilers and garden seats. Their Royal Mill, in Atlas Street, closed in 1962/3, the front demolished to make way for the M65 motorway.

Wooden rollers treated for woodworm, and turned down on a lathe to a reduced diameter. Rollers sheathed with stainless steel tubes of ¼" wall thickness - the most expensive items of the project. Drive and transfer wheels re-fitted and painted as per frame and components, and handle coated with two applications of sealing woodstain.

Rollers installed and transfer wheels cover fitted. Strips of wood fitted underneath original wooden top board, with a small gap between - to hold printing paper out of the way until nipped by rollers - and treated as per handle. Print bed can be sealed medium density fibreboard (MDF) or sheet steel. Mangle now a printing press, for linocuts, plate engravings and etchings, and woodblocks (up to tooth depth of transfer wheels), to a maximum of 20 inches wide.

Taywil was a brand of Taylor and Wilson, of Clayton, near Accrington, Lancashire. Founded in 1866, they made washing and mangling machines, and step-ladders. Later Taywil's trade listings included gas-heated boilers and garden seats. Their Royal Mill, in Atlas Street, closed in 1962/3, the front demolished to make way for the M65 motorway.

Labels:

Design,

Engineering,

Engraving,

Shed Wonders,

Vintage Technology

12 May 2014

Philips Pancake Loudspeaker

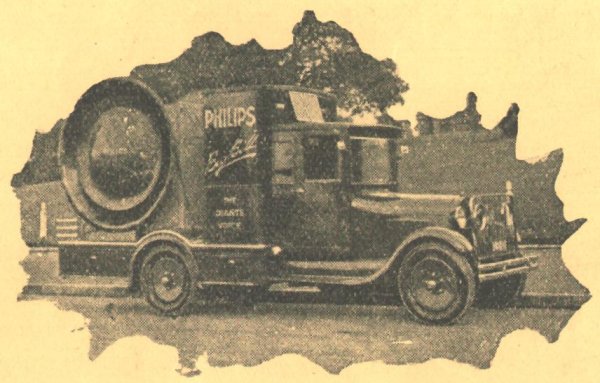

Shaped by the industrial designer Louis Kalff, the Philips 'pancake' or 'shaving-plate' loudspeaker was available in three diameters. The Model 2003, of 16 inches, was introduced in 1927, price £6 10s 0d. The Model 2015, of 14 inches, price £5 5s 0d, was introduced in 1928, when the larger model became known as the Senior and the smaller as the Junior.

When Philips introduced, in 1929, the Model 2007, of 18 inches, price £7 10s 0d, it was unaccountably marketed as the Peter Pan. This largest model featured a three-position rotary switch in the connecting lead, allowing for alteration in impedance and, hence, tone. The horseshoe magnet, balanced armature and parchment cone of the loudspeaker sit behind the inner Bakelite dish, the outer parabolic bowl acting as a sound reflector.

Whilst the Model 2015 could be had only in maroon Bakelite (what Philips for trademark reasons called Philite) the two larger models could be had in brown, buff, maroon, and marbled colours. This Model 2003 has glorious gold patterning, resulting from the inclusion in the Bakelite mix of brass powder.

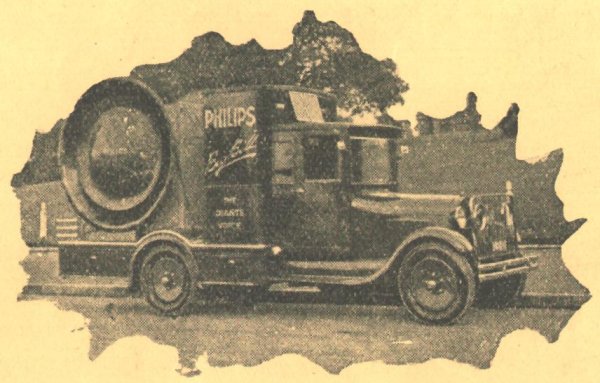

Although without a cabinet, the Model 2003 weighs a hefty seven pounds, partly due to the cast iron foot upon which it stands. The heaviest version though was Philips of Sydney's 1929 promotional Big Bill, a Ford Model A truck made to look like it carried a giant pancake, but actually packing a 500w public address system. Production of pancake loudspeakers continued at Eindhoven until 1930.

Although without a cabinet, the Model 2003 weighs a hefty seven pounds, partly due to the cast iron foot upon which it stands. The heaviest version though was Philips of Sydney's 1929 promotional Big Bill, a Ford Model A truck made to look like it carried a giant pancake, but actually packing a 500w public address system. Production of pancake loudspeakers continued at Eindhoven until 1930.

When Philips introduced, in 1929, the Model 2007, of 18 inches, price £7 10s 0d, it was unaccountably marketed as the Peter Pan. This largest model featured a three-position rotary switch in the connecting lead, allowing for alteration in impedance and, hence, tone. The horseshoe magnet, balanced armature and parchment cone of the loudspeaker sit behind the inner Bakelite dish, the outer parabolic bowl acting as a sound reflector.

Whilst the Model 2015 could be had only in maroon Bakelite (what Philips for trademark reasons called Philite) the two larger models could be had in brown, buff, maroon, and marbled colours. This Model 2003 has glorious gold patterning, resulting from the inclusion in the Bakelite mix of brass powder.

Although without a cabinet, the Model 2003 weighs a hefty seven pounds, partly due to the cast iron foot upon which it stands. The heaviest version though was Philips of Sydney's 1929 promotional Big Bill, a Ford Model A truck made to look like it carried a giant pancake, but actually packing a 500w public address system. Production of pancake loudspeakers continued at Eindhoven until 1930.

Although without a cabinet, the Model 2003 weighs a hefty seven pounds, partly due to the cast iron foot upon which it stands. The heaviest version though was Philips of Sydney's 1929 promotional Big Bill, a Ford Model A truck made to look like it carried a giant pancake, but actually packing a 500w public address system. Production of pancake loudspeakers continued at Eindhoven until 1930.

Labels:

Curiosities,

Design,

Engineering,

Vintage Technology

08 May 2014

Edgbaston Bunker

Below the garden of what was originally an Edwardian family residence in sedate Meadow Road, Edgbaston, Birmingham, lies a Cold War bunker. Constructed in 1954 to be used by up to 80 civil defence bureaucrats in the event of nuclear war, the extensive facility is a single-storey structure in concrete, with steps down from one entrance (top) and up to two fire exits (below).

The bunker could produce its own power, using diesel engines and generating sets, and had its own store of water. Never used for its intended purpose, in 1956 the space provided temporary shelter to refugees who had fled the Hungarian Uprising.

The mansion and surrounding land, including the bunker, was sold by Sandwell Metropolitan Council, for the West Midlands Fire and Civil Defence Authority, in 1990. The council made it a rather insane condition of the sale that, if nuclear war had not broken out by 2003, the bunker was to be demolished. It's still there.

At points during the 1990s the bunker was reportedly used for raves. It was at some juncture converted by the owners into a social club, complete with bar (above), pool table, band practice room, and skittles alley, originally the main corridor (below).

The naivety of those 'preparing' for nuclear war is illustrated by the fact that the bunker lies downhill from a large reservoir, damage to which would have flooded the secure site. Ironically, it was fire, in the form of arson, that ultimately did for something that would supposedly survive a nuclear attack.

Labels:

Cold War,

Curiosities,

Engineering,

Military

20 April 2014

Bakelite Box - Ekco PB505

The alternating current PB505 was released by Ekco in 1939, and was available in both a wooden cabinet and this 'walnut' Bakelite one, the same chassis in each. There are nine push buttons for pre-set stations. The cabinet was shared with the AC-only PB507 and the AC/DC PBU505. A variant of the cabinet was used again, after WWII, for the more common A21, released in November 1945. The latter can be recognised by having five, instead of nine, push buttons.

Labels:

Design,

Ekco,

Vintage Technology

13 April 2014

April Fools' Car Show 2014

The third running of the April Fools' Car Show, held at Canal Central in Maesbury Marsh, Shropshire, featured everything from the agricultural to the seriously exotic. The above McCormick Farmall, a brand of America's International Harvester, is a row-cropper, built in France, and looked very fine in its new paint.

From Telford came a lovely Jensen FF. Built between 1966 and 1971, the Jensen Ferguson Formula was the first production car to feature four wheel drive - from Ferguson Research Ltd - and anti-lock brakes, the Dunlop Maxaret system, and is five inches longer than its sister Interceptor. Placed third in show.

Show winner was a stunning 1947 Jaguar Mark IV 3½ litre cabriolet. The 3½ litre was introduced in 1938. This example has a very unusual two-door body, all the panel and mechanical work undertaken by its owner. This year's steam came in the form of a 1924 Clayton and Shuttleworth road roller, Ironside.

Labels:

Engineering,

Industrial Heritage,

Petroliana

09 April 2014

Bishkek - Brutal & Beautiful

The capital of the Kyrgyz Republic, Bishkek, is a city of concrete on an Altaic plain - altitude 2,600 feet - just north of the Ala-Too portion of the Tian Shah mountain range, which boasts peaks over 15,900 feet. A dramatic setting for a time capsule of concrete Soviet Brutalist architecture.

The Kyrgyz Republic gained its political independence from the USSR in 1991. The White House, of seven storeys and faced with marble, was built just six years previously. Originally the headquarters of the Communist Party's Central Committee for the sometime Kirghiz 'Republic', it is now the presidential offices.

On Ala-Too (once Lenin) Square is the Historical (once Lenin) Museum, of 1984. The square is enormous, designed to both impress and intimidate, but the surface is subject to subsidence due to poor substrate. Out the back of the museum is the giant statue of Lenin that previously stood out front, but now points into history.

Appended to the headquarters of Kyrgyz Telecom, also the post office, is a tower that houses a clock presented by Armenia in 1984. This broke down in 2000 and was silent until 2013. It sounds exactly like the Great Clock of the Palace of Westminster.

On Togolok Moldo Street is the National Centre of Cardiology and Internal Medicine, the centrepiece of the republic's efforts to rebuild its healthcare system, which has suffered due to sharp cuts in expenditure since 1991. The UK's hospitals often look brutal unintentionally. This is the real deal.

Hand-in-hand with health often goes sport. The nearby Sports Palace (above) was built in 1974 as part of the modernisation of the city, and is Bishkek's largest indoor venue, with seating for 2,500. The statue is of Kojomkol, born 1889, seven feet five inches tall, and famous for his feats of strength.

Bishkek is a bustling place, without being manic, and there are plenty of signs of a café life for the well-heeled. Yet the residential areas are largely of Soviet bloc blocks, architecturally interesting, even beautiful, but not necessarily much fun in which to live. The Ala-Too Cinema, likely of the late 1960s, adds some colour.

The Kyrgyz Republic gained its political independence from the USSR in 1991. The White House, of seven storeys and faced with marble, was built just six years previously. Originally the headquarters of the Communist Party's Central Committee for the sometime Kirghiz 'Republic', it is now the presidential offices.

On Ala-Too (once Lenin) Square is the Historical (once Lenin) Museum, of 1984. The square is enormous, designed to both impress and intimidate, but the surface is subject to subsidence due to poor substrate. Out the back of the museum is the giant statue of Lenin that previously stood out front, but now points into history.

Appended to the headquarters of Kyrgyz Telecom, also the post office, is a tower that houses a clock presented by Armenia in 1984. This broke down in 2000 and was silent until 2013. It sounds exactly like the Great Clock of the Palace of Westminster.

On Togolok Moldo Street is the National Centre of Cardiology and Internal Medicine, the centrepiece of the republic's efforts to rebuild its healthcare system, which has suffered due to sharp cuts in expenditure since 1991. The UK's hospitals often look brutal unintentionally. This is the real deal.

Hand-in-hand with health often goes sport. The nearby Sports Palace (above) was built in 1974 as part of the modernisation of the city, and is Bishkek's largest indoor venue, with seating for 2,500. The statue is of Kojomkol, born 1889, seven feet five inches tall, and famous for his feats of strength.

Bishkek is a bustling place, without being manic, and there are plenty of signs of a café life for the well-heeled. Yet the residential areas are largely of Soviet bloc blocks, architecturally interesting, even beautiful, but not necessarily much fun in which to live. The Ala-Too Cinema, likely of the late 1960s, adds some colour.

Labels:

Architecture,

Design,

Photography,

Travel

08 April 2014

Istanbul - Blue Mosque

The Sultan Ahmed Mosque, popularly known as the Blue Mosque because of the dominant colour of the interior decoration, must be one of the most visited buildings on the planet, but no pre-reading prepares for its calm, stunning beauty.

The mosque was built in just seven years, starting 1609, on the orders of Ahmed I, upon the site of the palace of Byzantium's emperors. The architect, Sedefkar Mehmed Agha, designed an extraordinarily grand space composed of a main dome surrounded by eight smaller domes. The mosque boasts six minarets, instead of the normal maximum of four, the first to do so.

The interior is simply gorgeous, over 20,000 handmade ceramic tiles from Iznik (Nicaea) at the lower levels and upon the massive piers, the decorative scheme at higher levels executed in paint. There are over 200 subtle stained glass windows. Humankind be praised.

Labels:

Architecture,

Art,

Design,

Engineering,

Travel

07 April 2014

Istanbul - Balat

Balat, traditionally a Jewish quarter, is a part of the Fatih district of Istanbul. It is located on the western side of the Golden Horn, and forms part of the old city of the peninsular, the erstwhile Byzantium and Constantinople.

The Jews began to leave Balat after the major earthquake of 1894, and the quarter is an intriguing mix of grandeur and neglect, some buildings holding up others. Few tourists make it from the grand bazaar to this quarter, but more should. Ruin porn at its best.

The Jews began to leave Balat after the major earthquake of 1894, and the quarter is an intriguing mix of grandeur and neglect, some buildings holding up others. Few tourists make it from the grand bazaar to this quarter, but more should. Ruin porn at its best.

Labels:

Architecture,

Photography,

Travel

21 March 2014

Anderton Boat Lift, Northwich

The Weaver Navigation was completed in 1734, allowing swift transportation from the Cheshire 'salt towns' to the River Mersey. In 1777 opened the Trent and Mersey Canal, at Anderton close to, but fifty feet above, the navigation, and providing a connection to Stoke-on-Trent. In 1793 a basin was excavated on the north side of the navigation, enabling goods to be trans-shipped by crane and inclined plane. To address significant traffic growth, the engineer Edward Leader Williams designed a lift of two counterbalancing water-filled caissons, supported by interconnected hydraulic rams: additional water need only be added to one caisson for this to descend and its twin to rise, with fine adjustments requiring just a 10hp steam engine.

The hydraulic engineer Edwin Clark undertook the detailed design. The caissons, each 75 feet long, 15.5 feet wide, 9.5 feet deep, and weighing 252 tons when filled, were supported by hydraulic rams - hollow cast iron pistons, 50 feet long and three feet in diameter, inside buried cast iron chambers of the same length but of 5.5 feet diameter. The original superstructure consisted of just seven hollow cast iron columns, to guide the caissons, connecting at the top to a 165 feet long wrought iron aqueduct, gated at each end. The ride took three minutes, although were a caisson raised or lowered independently, using only the power of the steam engine, this extended to 30 minutes. Construction commenced in 1872, and the lift opened in 1875.

Unfortunately, canal water was used as the hydraulic fluid, and the rams corroded badly. The engineer Colonel Saner designed a replacement system of electric motors, wires, counterweights and pulleys to allow each caisson to move independently. The superstructure was strengthened by the addition of steel A-frame buttresses, and 36 cast iron counterweights, of 14 tons each, were installed. The pulleys were driven by a 30hp motor. The conversion work was undertaken between 1906 and 1908.

The lift closed in 1983 due to the discovery of extensive corrosion in the superstructure, but was fully restored between 2000 and 2002. Although the headgear and buttresses of 1906-8 remain in place - the weights form a children's maze nearby - the lift once again operates hydraulically, using oil-filled rams to drive each of the caissons separately. The Anderton and the Falkirk Wheel are the only operational boat lifts in the UK.

The hydraulic engineer Edwin Clark undertook the detailed design. The caissons, each 75 feet long, 15.5 feet wide, 9.5 feet deep, and weighing 252 tons when filled, were supported by hydraulic rams - hollow cast iron pistons, 50 feet long and three feet in diameter, inside buried cast iron chambers of the same length but of 5.5 feet diameter. The original superstructure consisted of just seven hollow cast iron columns, to guide the caissons, connecting at the top to a 165 feet long wrought iron aqueduct, gated at each end. The ride took three minutes, although were a caisson raised or lowered independently, using only the power of the steam engine, this extended to 30 minutes. Construction commenced in 1872, and the lift opened in 1875.

Unfortunately, canal water was used as the hydraulic fluid, and the rams corroded badly. The engineer Colonel Saner designed a replacement system of electric motors, wires, counterweights and pulleys to allow each caisson to move independently. The superstructure was strengthened by the addition of steel A-frame buttresses, and 36 cast iron counterweights, of 14 tons each, were installed. The pulleys were driven by a 30hp motor. The conversion work was undertaken between 1906 and 1908.

The lift closed in 1983 due to the discovery of extensive corrosion in the superstructure, but was fully restored between 2000 and 2002. Although the headgear and buttresses of 1906-8 remain in place - the weights form a children's maze nearby - the lift once again operates hydraulically, using oil-filled rams to drive each of the caissons separately. The Anderton and the Falkirk Wheel are the only operational boat lifts in the UK.